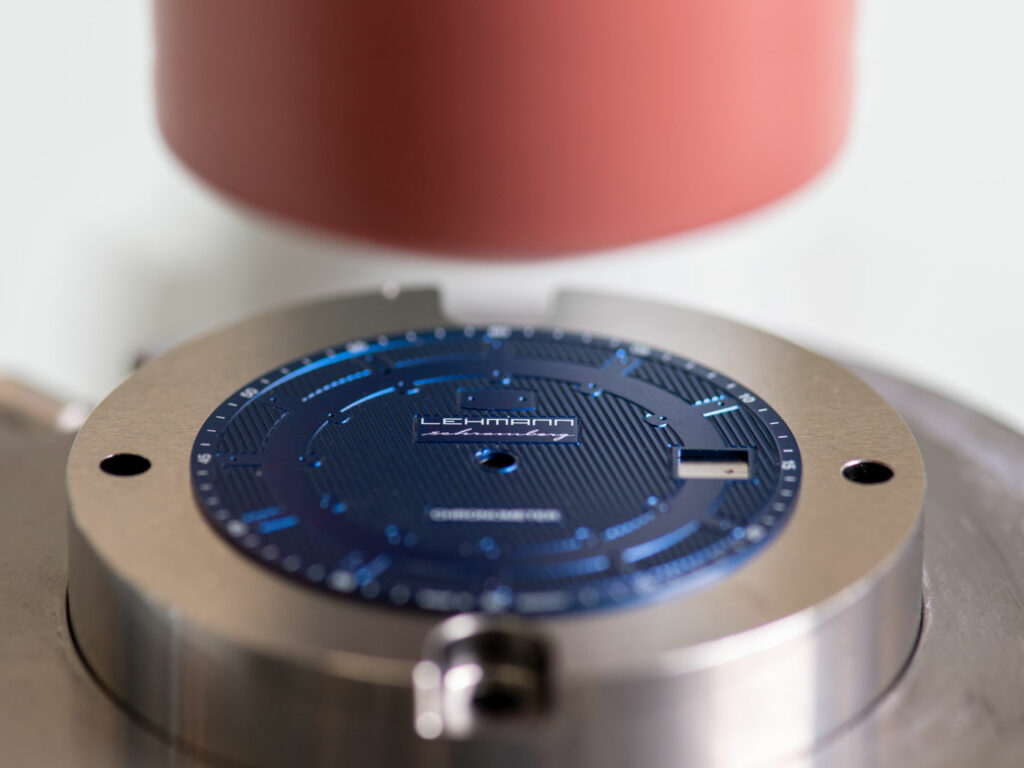

In-house dial manufacture

The goal of the Lehmann watch factory was to be able to work autonomously in as many areas as possible. One major step was the establishment of the in-house dial manufactory, which formed part of the newbuild and refurbishment project. We now electroplate bridges and similar micro-components for the watches in electroplating baths. With considerable investment, a perfect environment was created for this very demanding and varied activity. The ultrafine watch parts are gold and rhodium-plated or luminous details are added to coated hands and indices.

The primary task however is the manufacture of the dials, with all appliqués, from blank to end product.

Complete dial

manufacture

The Lehmann dial manufactory turns blanks into finished dials. The prepared blanks are turned and milled on Lehmann machinery. The machines are specially designed for the intricate engraving. However, some engraving, such as the sunburst decoration, is applied by hand for certain models.

Electroplating

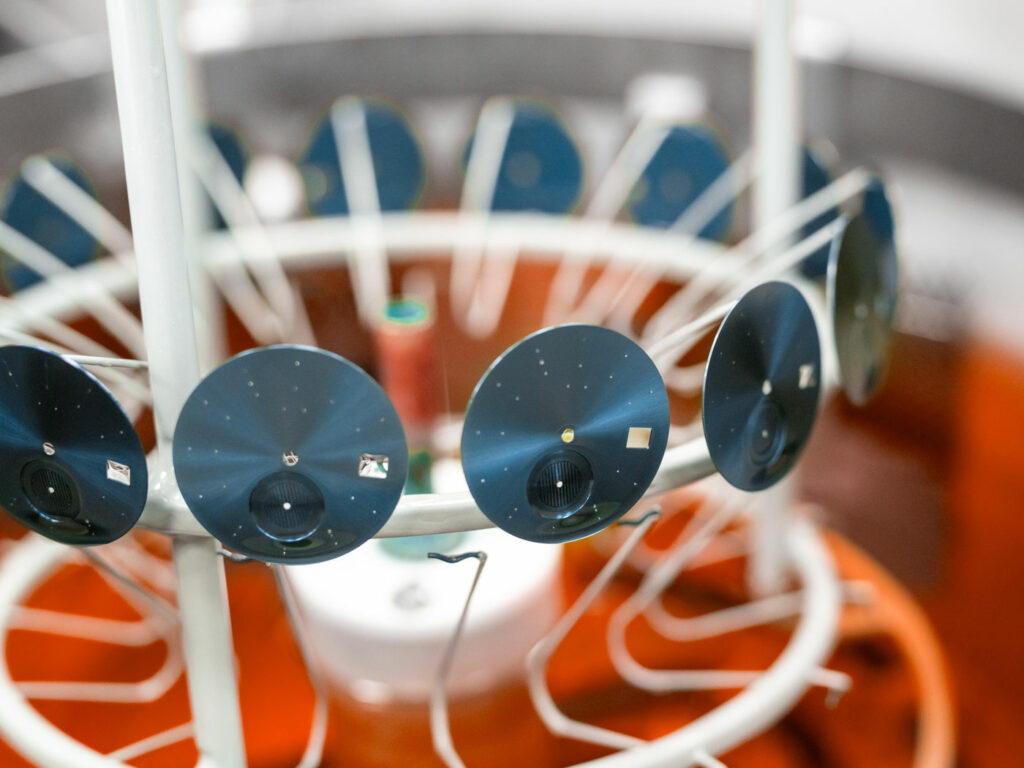

After mechanical finishing, the dials are electroplated or lacquered, depending on the design of the dial. These processes are completely different. In the case of electroplating, electrolysis is used to apply even metal coatings to the part. For this purpose, the blanks are immersed in an electroplating bath for a specific time period.

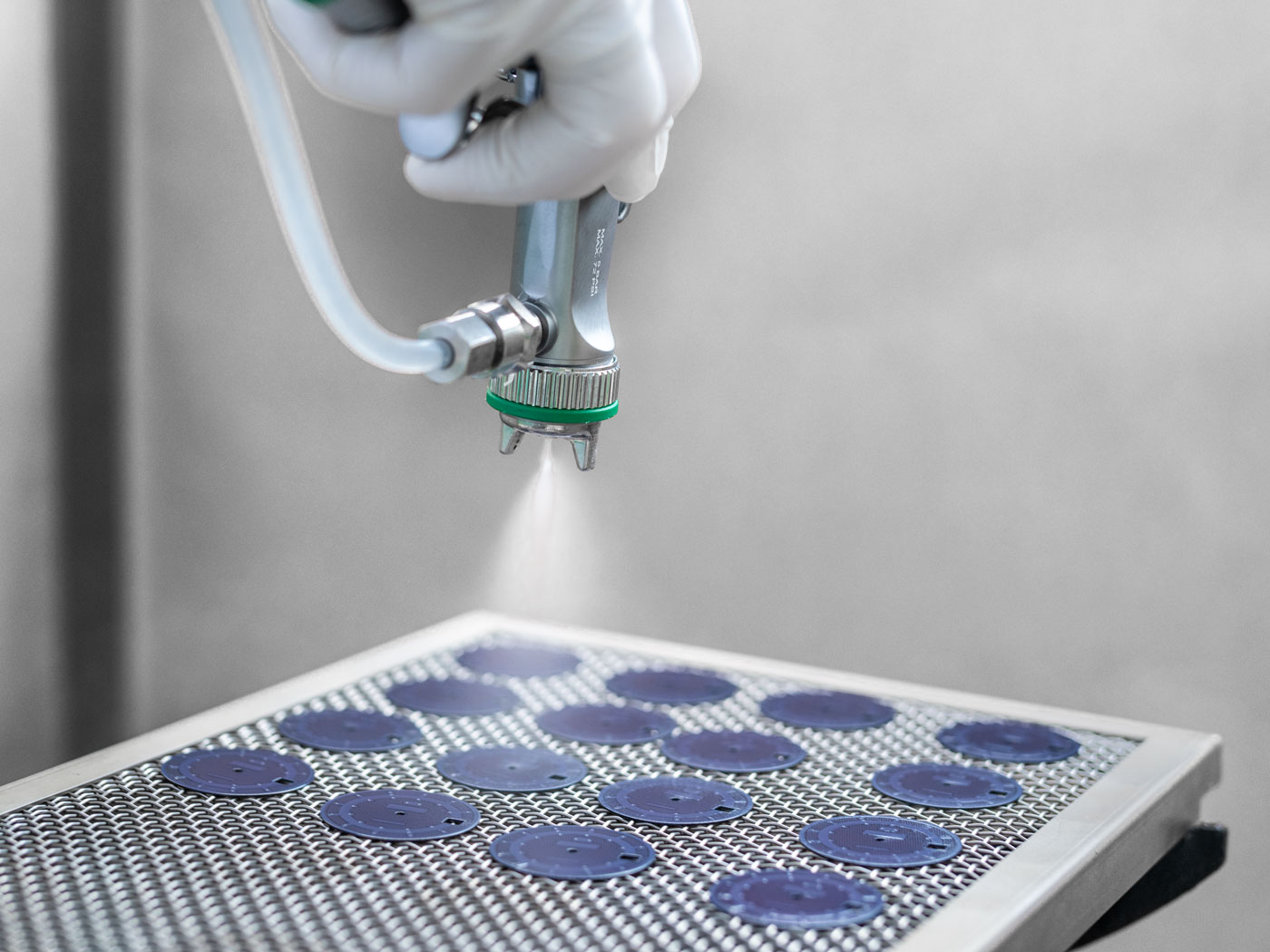

Lacquered dials

If the dial is lacquered, an ultrafine, even layer of paint is sprayed on by hand and then dried in an oven. Both processes require a lot of experience and a professional working environment.

Printing

The pad printing process is used to print the dials. In this very demanding operation, all the requisite printing elements are applied to the dial in their precise positions with the help of a soft stamp and what is known as the cliché, the negative mould. The process is repeated to achieve the perfect colour density on the dial. Depending on the model, different pressures are required within the sequence.

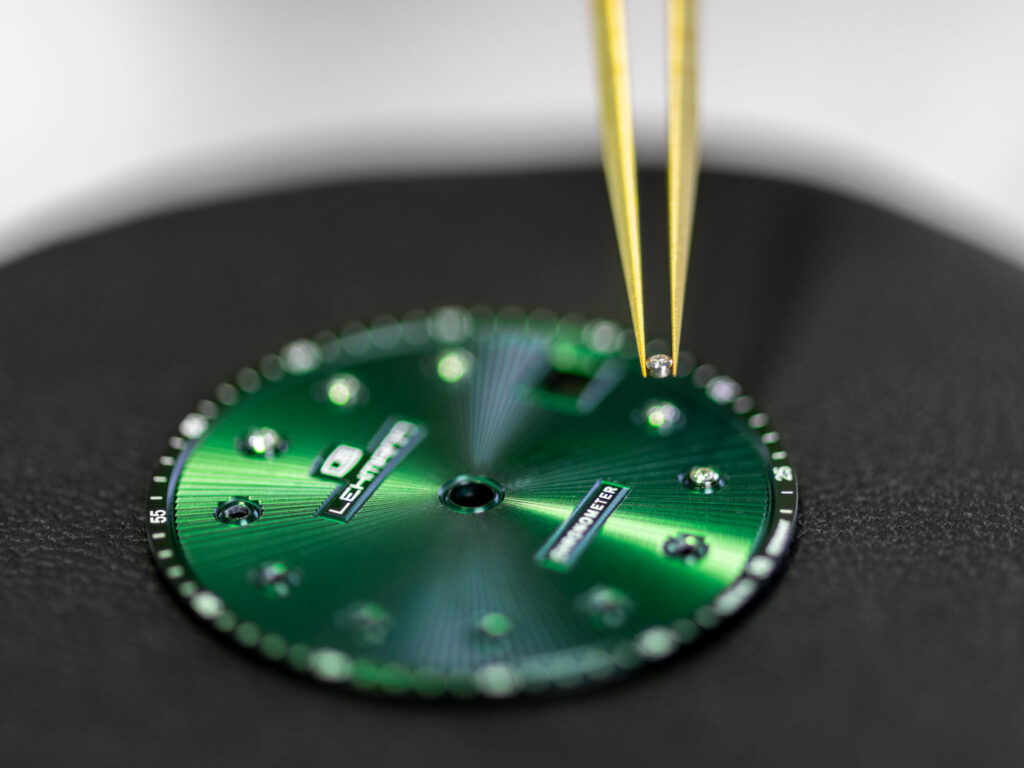

The dial appliqués

With the greatest of care, appliqués are applied to the already-coated dial. All appliqués, i.e. indices, date window or logo and also the white-gold diamond settings are made in-house. They receive their particular shine from mechanical finishing with a diamond tool. Before further processing, all parts are electroplated, some with luminous details added, before being applied to the dial by hand.